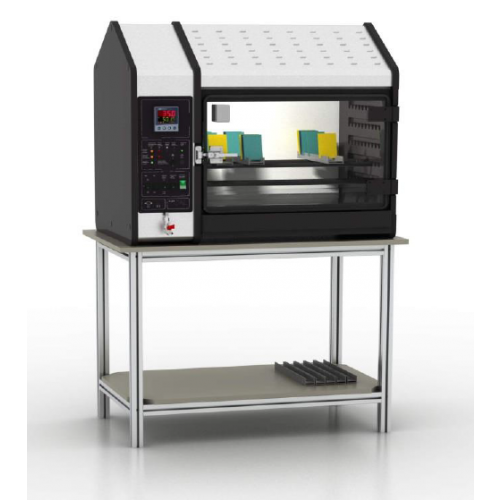

VLM CON FL Water Condensation Cabinets

Cost-effective solution for basic water condensation and SO2 corrosion tests

Compact and easy to operate benchtop cabinets are designed for conducting water condensation (constant humidity) tests

User friendly, VLM intuitive control system with colour display and preconfigured test parameters installed

VLM CON FL Water Condensation Cabinet Range

Cost-effective solution for basic water condensation and SO2 corrosion tests

Models Available:

CON 300-FL (+50°C)

CON 400-FL (+60°C)

These compact and easy to operate benchtop cabinets are designed for conducting water condensation (constant humidity) tests pursuant to the most common international corrosion test standards such as:

DIN EN ISO 6270-2:2005

ASTM D2247

Cabinets with AIR or ADO option are applicable for the additional water condensation tests:

Alternating temperature (AT)

Alternating temperature and humidity (AHT)

The (KES) version of CON 300-FL test cabinet is suitable for conducting Kesternich tests acc. to:

DIN EN ISO 6988 (DIN 50018)

Customer Benefits

- Compact benchtop design

- The patented VLM technology allows the best possible reproducibility of the temperature conditions being created in the test chamber regardless of the environmental conditions and geographical location – the same type of VLM corrosion test chamber will produce the same test results in any geographical region

- The test chamber made of steel is more robust and less susceptible to damages compared to the competitive products made of glass-reinforced plastic

- Lower cost of ownership compared to the competitive products where the test chamber is made of glass-reinforced plastic (shorter test periods, better energy efficiency, easier for service and maintenance, longer life cycle, more resistive to mechanical damages)

- User-friendly control system with pre-configured test parameters

The following Accessories are included:

- 5 rods for supporting test specimen

- 2 m exhaust hose Ø 50 mm

- 2 m drain water hose Ø 18 mm

- 1 female connector for compressed air hose (size no. 5)

-

Relevant Test Standards

Water condensation tests:

DIN EN ISO 6270-2:2005

BS 3900 F2

BS 3900 F15

ASTM D2247Technical Specifications

Model CON 300-FL (+50°C) CON 400-FL (+60°C) Capacity ca. 300 L ca. 400 L Inner test chamber dimensions W/D/H1/H2 ca. 800 x 605 x 533/720 mm ca. 800 x 605 x 733/920 mm Outer dimensions of the casing (overall) W/D/H ca. 1100 x 680 x 890 mm ca. 1310 x 670 x 1933 mm (height including bench cabinet) Temperature Stability ±0,5°C ±0,2 C° Required power supply 230V, 50/60Hz, 700W 230V, 50/60Hz, 800W Materials used the test chamber is made of stainless steel, bottom coated with ECTFE, sidewalls made of Polyethylene with milled openings for supporting rods the test chamber is made of stainless steel, bottom coated with

ECTFE, sidewalls made of Polyethylene with milled

openings for supporting rodsHeating Flat Micanite heater under the bottom of the chamber for fast and uniform heat transfer Flat Micanite heater under the bottom of the chamber for

fast and uniform heat transferSensors - In basic type: 1x corrosion resistant and highly sensitive temperature sensor

- In CWC type: 2x corrosion resistant and highly sensitive temperature sensors (floor and roof)- In basic type: 1x corrosion resistant and highly sensitive

temperature sensor

- In CWC type: 2x corrosion resistant and highly sensitive

temperature sensors above the floor and under the roofAeration (type AIR) timer-controlled built-in fan airflow ca. 16 m³/h timer-controlled built-in fan airflow ca. 30 m³/h Timer (Jumo dTRON) Two-channel timer for the automated switch over from heating to aeration mode Two-channel timer for the automated switch over from heating

to aeration modeWeight 110 kg 256 kg Communication RS 232 interface RS 232 interface Other Specification

Model CON 300-FL (+50°C) CON 400-FL (+60°C) Purity demineralized water | filling volume | fitting < 5 μS/cm | ca. 3,5 L | ¾“ outer diameter

Option: Automatic water refill< 5 μS/cm / ca. 3,5 L / ¾“ outer diameter

Option: Automatic water refillTap water (connection type) Always via Ion-exchanging cartridge (¾“ outer diameter) Always via Ion-exchanging cartridge (¾“ outer diameter) Compressed Air 6-8 bar (connection nipple size 5) 6-8 bar (connection nipple size 5) Wastewater, drain Pipe fittings (spiral hose ID 19 mm) Pipe fittings (spiral hose ID 18 mm) Exhaust pipe outer diameter Pipe fitting (50 mm external diameter) Pipe fitting (50 mm external diameter) Number of supporting rods/max load 5 stainless steel rods coated with plastic / 30 kg each 5 stainless steel rods coated with plastic / 30 kg each Introduction of SO2 Self-closing inlet valve at the right-hand sidewall Self-closing inlet valve at the right-hand sidewall

-

Process Control

User friendly, microprocessor-based Jumo dTRON controller

Programmable timer function

Option: VisiCORR® software for visualisation of test trends, only in combination with RS 232 (only monitoring and documenting the test

Restricted access for authorised operators (security code)Operating system AIR and AWRF

Option: System for forced ventilation (AIR) with a variable speed fan for drying test specimens with environmental air

Option: Automatic water refill (AWRF) system suitable for AHT type of condensation testOperating system Constant Humidity (CH) with Controlled Water Condensation - CWC (according to ISO 6270-2 CH)

CWC system is the patented VLM technology which regulates the temperature gradient of exactly ΔT=1°C between the bottom and the roof of the test chamber – this is essential for an optimal condensation process in the test chamber at 100% RH regardless the environmental conditions outside the test chamber

Flat heaters under the bottom of the chamber for uniform and rapid heating of the water in the trough

Temperature stability in the chamber ±0,2°C

Air fan with the manually adjustable rotation speed for controllable drying of specimen in the Drying Phase