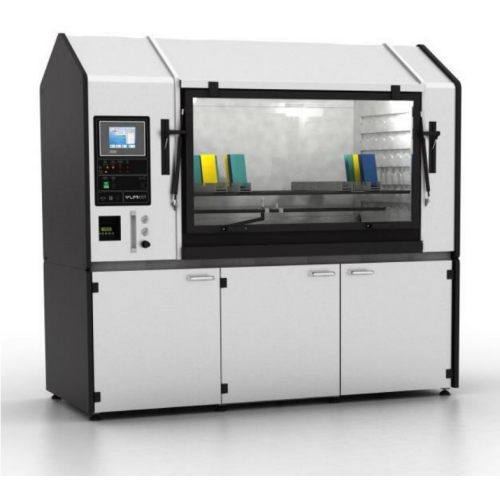

VLM CORR CC 1000 FL +80 °C Cyclic Corrosion Testing Chamber

Highly sensitive electronic mass flow meter

High flexibility in choosing the basic type of the test chamber

VLM DosiCORR® ED Electronic Gas Dosing System for the Kesternich Test

Highly sensitive electronic mass flow meter

The electronic gas dosing system for the Kesternich test (DosiCORR® ED) in SO2 environment can be fitted to virtually any VLM test chamber (except for the SAL range) and regardless of the controller used. However for the cost-effective reasons only the test chambers belonging to the VLM mid-range (CON, CON-SAL and CCT) featuring Jumo dTRON and Jumo Imago controller will be equipped with this option. This flexibility is possible due to the fact that the DosiCORR® ED gas dosing system operates independently from the process controller built into the basic test chamber.

The operation of DosiCORR® ED gas dosing unit is simple. At the beginning of the Condensation test the control button is pressed on the control display of the DosiCORR® ED gas dosing unit which releases the

predefined volume of SO2 into the test chamber.

Customer Benefits

- High flexibility in choosing the basic type of the test chamber – the DosiCORR® ED system operates in combination with (almost) all chamber types and all controllers

- User friendly operation

- Highly sensitive electronic mass flow meter allows accurate gas dosing

- Modular design of VLM test chambers allows easy adding of the DosiCORR® ED option long after the chamber has been commissioned

- The complete system is designed according to the highest safety standards; the DosiCORR® ED system with SO2 bottles is enclosed in a separate casket which is continuously ventilated

-

Safety

SO2 is a poisonous gas and for this reason was the safety of the operating personnel one of the main DosiCORR® ED design parameters. For this reason this system meets the highest safety standards. Some of the features are:

- The SO2 bottles are kept in a permanently ventilated casket inside the bench underneath the test cabinet

- The casket is made of a special, fire-resistant material specially designed for this purpose

-

Relevant Test Standards

- Cyclic Climate Tests:

- DIN EN ISO 11997-1:2006 Cycle B (previously VDA 621-415)

- VW PV 1210 (climate module required)

- Nissan CCT 1

- Renault ECC1 (climate module required)

- Volvo STD 423_0014 (option)

- GM GMW 3172 (option)

- IEC-60068-2-52 KB

- Salt Spray Test:

- DIN EN ISO 9227

- DIN 50942, DIN 53167

- ASTM B 117-73, ASTM B 287-74

- ASTM B 368-68

- ISO 7253 ISO 3678

- BS 1224, BS 2011, BS3900 F4

- BS 3900 F12

- BS 5466 Part I, BS 5466 Parts 2 + 3

- NFX 41002,

- AS 21331 Section 3.1

- SIS 1841190

- JIS Z 2371

- Condensation water test:

- ISO 6270-2

- BS 3900F2, BS 3900 F15

- ASTM D2242

- Cyclic Climate Tests: