MTS Jet Mixing

Jet Mixing systems for effluent treatment

Jet Mixing Systems

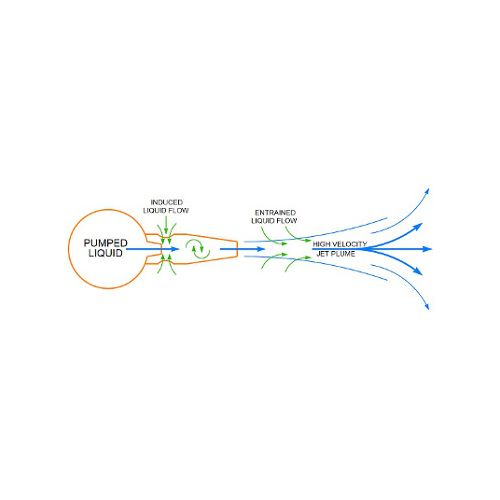

The MTS jet mixing systems are a highly turbulent submerged mixer technology. Jet mixing is a highly efficient method to distribute mixing energy while minimizing horsepower requirements.

Each MTS mixing jet nozzle consists of two liquid nozzles nested together. The primary flow is typically provided by either a dry-pit or submersible pump that draws suction from the tank being mixed. The primary flow is pumped through the inner mixing jet into the outer mixing jet creating an eduction effect and induces additional circulation through the three entrainment holes in the outer mixing jet. The combined flows are mixed in the outer mixing jet and jetted out into the bulk fluid as a homogenous, high velocity liquid plume. Velocity gradients in the liquid plume entrain additional liquid recirculation in the bulk fluid.

|

JET MIXING ADAVANTAGES |

JET MIXING APPLICATIONS |

- Long Life- Highly Efficient- Low Capital Cost- Reduced Installation Cost- No In-Tank Maintenance Items- Superior Corrosion and Abrasion Resistant Materials of Construction |

- Flash Mixing- Equalization- Liquid / Liquid Blending- Solids Suspension- Neutralization |

More from MTS