Kurabo Technologies

Kurabo designs and manufactures plants, equipment, and machines for environmental production, and industrial and household waste recycling.

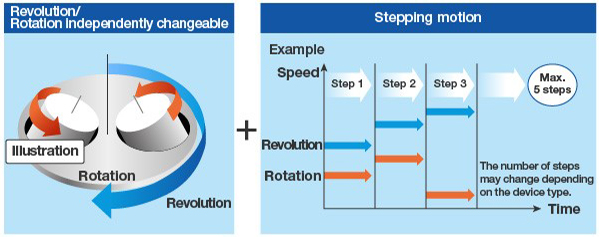

Mixing / deaerating can be conducted simultaneously within a short time by rotating and revolving (planetary rotating) a container of materials without using a mixing rod / blade or vacuum device.

Two unique mechanisms

Variable motion, continuous step mechanism (maximum five steps)

Wider range of applications

Examples of applicable materials

Epoxy resin, silicon resin, acryl resin, urethane resin, polyimide, wax, grease, lubricant, oil, water, various kinds of solvents, silver powder, gold powder, copper powder, carbon, alumina, pigment, phosphor, calcium carbonate, tungsten, titan, glass powder, glass fiber, silica, aluminum powder, pearl, various kinds of fibers, silver paste, carbon paste, copper paste, UV ink, oily ink, special paint, diamond, Various kinds of mineral resources, abrasive

Examples of product use

Conductive / resistance / insulation paste Condenser, resistor, secondary battery, fuel battery, solar battery panel PCB resist / padding ink Green sheets, heat dissipation sheets, heat insulators Optical fiber cables Slurry, carbon nano-tubes Abrasive grains, polishing of small parts, particle grinding

LED sealing agents, LCD sealing agents, liquid crystal sealing agents for organic EL Conductive material and sealing agents for touch panel displays Various kinds of paste, membranes, film materials for PDP

Medical materials, pharmaceuticals, dental materials, ointment Lens coating materials Lipsticks, mascaras, nail gel, cream, foundation Print ink, paint color matching Sealing materials