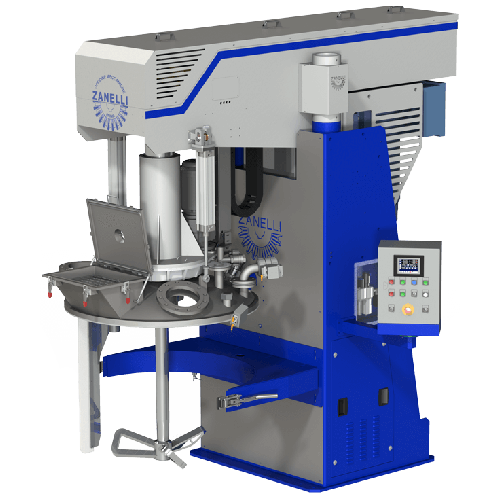

Zanelli Titanium Line Single Shaft Butterfly Mixer

The Zanelli Titanium Line BIRG is a single shaft butterfly mixer

Zanelli Titanium Line Single Shaft Butterfly Mixer

The Zanelli Titanium Line is a single shaft butterfly mixer and has an electrical motor up to 110 kW complete with a frequency converter. This machine is suitable to mix products having a high viscosity up to about 1.000.000cP. The movable vessel maximum capacity available is up to 1700 litres. The vertical stroke movement is obtained through two pneumatic pistons. This model is also fitted with a rotating scraper.

MIXER, UNDER VACUUM, TITANIUM LINE MODEL BIRG WITH ROTATING SCRAPER

Main transmission Electrical motor complete with frequency converter. Reduction gear with parallel axes. The power transmission between the electric motor and the mixing shaft takes place through pulleys and belts with profiles and appropriate sizes.

Auxiliary Hydraulic Power Pack Hydraulic power pack positioned in the machine structure, complete with an electric motor, coupling strainer, coupling, pump, solenoid valves, oil level, vent, drain cock and safety devices. The power pack actuates the hydraulic cylinder, complete with a safety lock valve. The cylinder is placed in the centre of the two fixed columns and is suitable to lift up the entire mixing group.

Mixing tools Dispersion shaft in AISI 304 stainless steel, balanced with an adequate taper on the edge, in order to ensure the elimination of vibrations even in the most critical stages of processing and at high-speed rates. The change in speed of the mixing shaft is obtained by means of an electronic system complete with a frequency drive (inverter). The advantage is that the operator has a range of speeds available but especially there is a high torque even at medium/low speeds. Continuously variable speed. The dispersion tool, supplied with the machine, is a butterfly impeller with an easy fixing to the shaft, easy to replace.

Rotating scraper group Rotation of the scraper is obtained via an electric geared motor coupled to a pinion and to a fifth wheel, both lodged within a sealed box, fixed to the lid. An AISI 304 stainless steel revolving sleeve is fixed to the rotating fifth wheel and supports scraper arm, tubular-shaped, built in a sturdy sheet of AISI 304 stainless steel, complete with a self-adjusting tang, suitable to support the lateral scraper blade, in AISI 304 stainless steel, complete with interchangeable screwed profile, made in a suitable material.

Mixing shaft vertical stroke The impeller vertical movement, called stroke, is obtained by 2 pneumatic pistons. The possibility to adjust the correct height of the mixing/dispersing tool, in relation to the quantity of product contained in the vessel, ensures high flexibility to the machine and also allows to optimize the mixing flow, granting fast incorporation of raw materials, and in case of the machine under vacuum a speedy air extraction from the product. The stroke is achieved by the sliding of a fixed sleeve, complete with bearings and seal rings, fixed to the lid, and by the mobile sleeve, coated with rectified hard-chrome, fixed to the mixing group, which also acts as bearings support of the mixing shaft.

Mixing vessel Vessel made of AISI 304 stainless steel. AISI 304 stainless steel reinforcement top ring. Intermediate band, in AISI 304 stainless steel, with fixings to support basement. Vessel with rounded bottom and connected to vertical plating. Discharge in the central part.

Frame The structure of the machine, called a frame, is composed of sturdy construction in carbon steel, treated with two-component epoxy paint. It is complete with a base plate with suitable holes for fixing to the floor, by means of chemical anchors brackets. Two columns, complete with sliding bushings, are fixed to the side of the structure and house two columns, coated with rectified hard-chrome, wear-resistant. This technical solution gives a high strength to the machine, even in the most critical phases of the production cycle, minimizing vibrations.

Models

BIRG: Undervacuum machine version with an independent revolving scraper and vertical movement of the mixing shaft during the various process phases by means of a sleeve and sliding cylinders.

AIRG: Machine with an independent reversing scraper and vertical movement of the mixing shaft during the various process phases by means of a sleeve and sliding cylinders.

BI: Undervacuum machine version with vertical movement of the mixing shaft during the various process phases by means of a sleeve and sliding cylinders.

AI: Machine in the standard version with vertical movement of the mixing shaft during the various process phases by means of a sleeve and sliding cylinders.

CI: Machine in standard version with vertical mixing shaft movement during the various process phases by protective bellows and sliding guides.

OPTIONS

- VACUUM PUMP

- KIT OF AUTOMATIC HOOKS TO LOCK THE LID DURING OVERPRESSURE INSIDE MIXING VESSEL

- KIT OF MANUAL HOOKS TO LOCK THE LID DURING OVERPRESSURE INSIDE THE MIXING VESSEL

- MIXING TOOLS OUT OF THE PRODUCT DURING THE VACUUM

- TEMPERATURE PROBE TO DETECT PRODUCT TEMPERATURE, FIXED INSIDE THE MIXING SHAFT

- VESSEL CLAMPING DEVICE WITH MANUAL CLAMP

- VESSEL CLAMPING DEVICE WITH AUTOMATIC CLAMP

- WEIGHING PLATFORM

- PC TO CONTROL THE MACHINE, FULLY AUTOMATED, WITH RECIPE MANAGEMENT

- MOVABLE WASHING HEADS LOW OR HIGH PRESSURE

- ATEX EXECUTION

-

Vertical Excursion

Vertical excursion of the dispersing shaft

The vertical movement of the mixing impeller, called excursion, occurs through the use of pneumatic pistons.

The possibility of adjusting the correct height in relation to the quantity of product contained in the tank guarantees high flexibility to the machine and also allows to optimize the mixing flows, assurance the fast incorporation of the raw materials and in the case of vacuum machine speeds up the air extraction from the product.

Electrical Motor

Main transmission

The main electric motor and speed reducer are both fixed to the mixing unit complete with pulley-type transmission and belts with profiles and dimensions suitable for the installed power.

Two Independent Columns

-

Applications

Inks, Glues, Mastics, Adhesives, Sealants, Plastics, Cosmetic Products, wall fillers, polyester stuccoes, silicones.